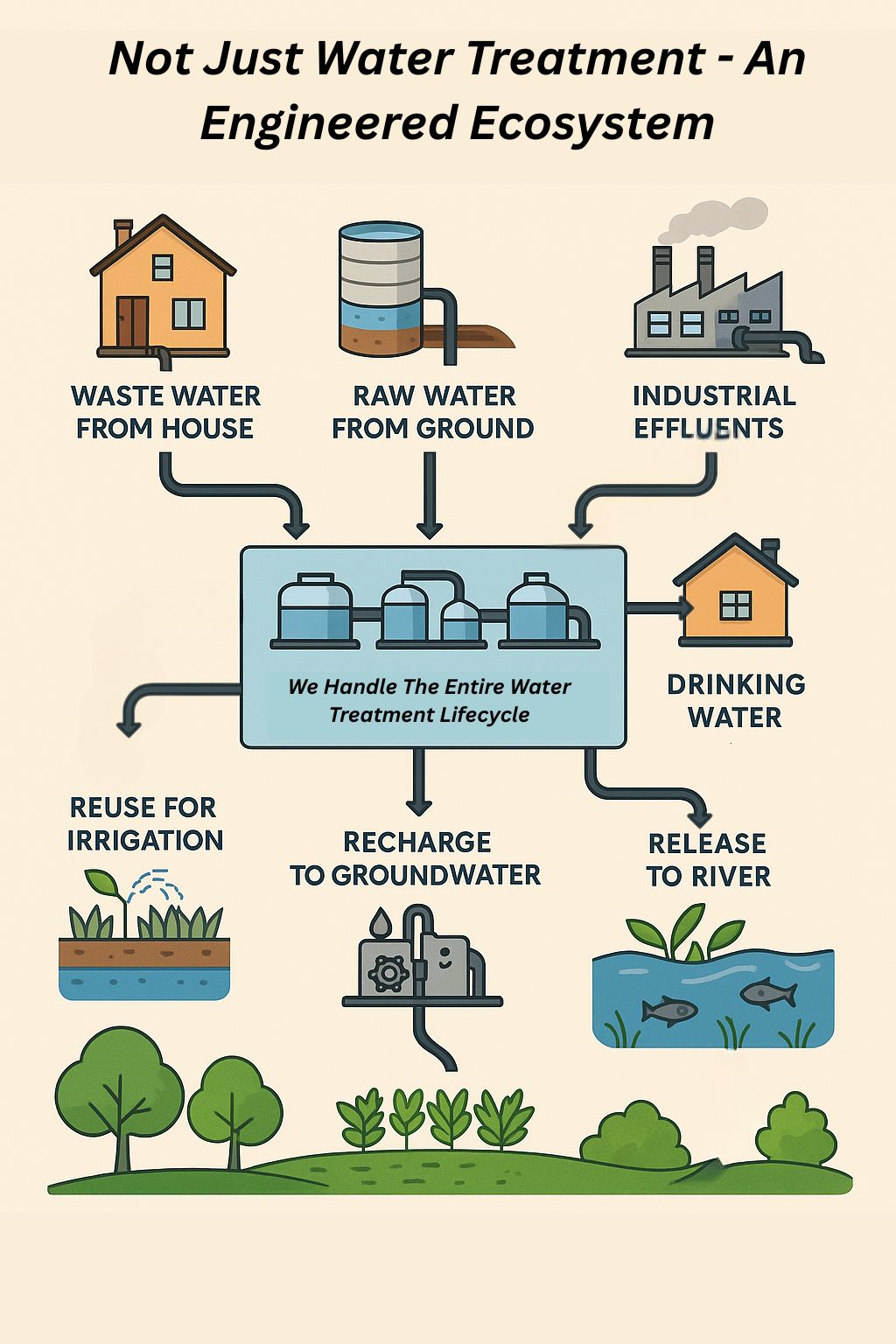

Giving Wastewater a Second Chance

360 Degree Water Treatment | Engineering |

Plant Installation | Maintenance

About Us

End-To-End Water Treatment Solution & Engineering

We at Seminal Water Infrastructure Pvt. Ltd. design, engineer and install Raw & Waste Water Treatment Plants spanning all segments catering to such universal basic needs, a number of such installations are in operation and more are in various stages of implementation.

And not only the Drinking Water, we serve the entire gamut of Raw Water Treatment for other applications also, such as DeMineralization Units and Membrane Filtration Units..

One Partner, Full Lifecycle

From first designs to final commissioning, Seminal Water Infrastructure Pvt Ltd – takes responsibility for the entire lifecycle of engineering, commissioning and maintaining water treatment plants for businesses, large facilities and complexes. Whether it’s a WTP, or a compact STP for a clinic or a complex ZLD system for a manufacturing plant, our in-house team designs, builds, retrofits, and sustains it all – seamlessly, without fragmentation.

Flexible, Future-proof Compliance

Regulations evolve. Today it’s CPCB introducing a new regulation; tomorrow it might be a new local pollution norm. Our water treatment plants and processes are customized as per the changing needs, and with buffers, a smart design, and a bit of foresight, you stay out of trouble. Quietly.

Built Around People

Engineering specs and features are essential, but not enough. An industry-grade water treatment plant has to be made keeping human capital in mind – the operators, the site engineers, estate managers… Our water treatment plants and processes are built not just for performance on paper but for real-world usability: logical planning, intuitive controls, adaptable designs, and post-commissioning services that actually respond.

100+ Reviews

Our Services

For making raw water suitable for human use, industrial processes, or sensitive environments. This includes : filtration plants, iron removal plants (IRP), RO and other Membrane Filtration systems. We also have expertise in swimming pool filtration, process water plants, and Softening & De-Mineralization Plants.

We design rainwater harvesting systems that collect, filter, and store rain from rooftops or open areas—reducing your use of municipal or borewell water. These systems are easy to maintain, cost-effective over time, and can be integrated with your existing plumbing or reuse setups. Ideal for buildings, factories, and campuses looking to cut water bills and use resources wisely.

We offer comprehensive wastewater and effluent treatment solutions including Packaged STPs, Industrial ETPs, and Municipal Waste Plants—along with advanced systems for handling combined sewage with food waste or effluents, and specialized liquid waste facilities. These are designed for efficient processing of domestic, industrial, and mixed-load discharges.

To enable water reuse, cost recovery, and regulatory compliance, we offer Advanced Water Recycling Systems, Zero-Liquid Discharge (ZLD) solutions for industries, and treated sewage reuse systems tailored for non-potable applications.

We offer drip irrigation setups that deliver water directly to the root zone—minimizing waste and maximizing plant health. Designed for landscapes, green belts, industrial lawns, and institutional campuses, these systems cut water use by up to 60% compared to sprinklers. Easy to automate, easy to maintain, and perfect for clients who want efficiency without overdesign.

End-to-End

Upgrades, Retrofits & Performance Optimisation

For ageing or underperforming facilities, we deliver Capacity Augmentation Projects, plant revamping and refurbishing, Balance of Plant packages, and automation with layout rationalisation—ensuring renewed performance and operational efficiency.

Softener

Our Process

Our Workflow Ethos:

Every engineering work takes a certain direction, a certain way of execution. However, we add more to this – our passion for what we do, our legacy and our combined experience of working with integrity:

It Starts With Listening:

Every project starts with a site visit. Ours too. But we observe. We don’t hear – we listen. And we stay long enough to understand the real requirements – the ones that appear after the noise settles.

We Design With Intention

It’s not just a CAD drawing for us. It’s our way of protecting the world at a time when clean water is direly needed, and wastewater is direly needed to be processed responsibly. But it’s not just about philosophy – we customize practicality and comply with just as responsibly.

We Map Every Millimetre

Once the thinking is done, we move to exactness. Line weights matter. So do margins, gradients, and who will open the control panel ten years from now.

We Procure With Care

Every component of the infrastructure we design – pipe, pump, panel – directly affects our reputation. Therefore, we source with care, responsibility and practicality. It’s not about ideology; – it’s about preserving our reputation and sustaining your facility.

We Assemble With Precision

On site, we work like guests with a responsibility. No overpromising. No cutting corners. Only a quiet commitment to finishing right.

We Do QA Without Assumptions

‘Good enough’ isn’t good enough for us. We have a data-driven, thorough QA protocol, and we sign off only after we are honestly sure about the outcome of our work.

We Make Machines Talk

Even a mechanical engineering job like ours requires smooth communication among systems. Our engineers are here to make sure that the flow metre talks to the controller, the sensors keep sending real- time data and the operators enjoy a truly automated water treatment solution.

We Stay Within Reach

Our Annual Maintenance Service (AMC) keeps facility managers off the tenterhooks. We believe people should be able to use our creations with confidence.

Proven Expertise Across Industries

Industries We’ve Served

Can’t see yours?

Talk To UsEvery site has two challenges: what comes in, and what must go out.

We treat both – raw water and waste – with the same accountability. Because CPCB norms don’t care where the mistake began.

Schedule an AppointmentCall for Service Today